1. Design philosophy and principles

Double helix design thinking

User demand axis: Mining explicit/implicit requirements through the Kano model

Technology implementation axis: Break through engineering contradictions based on TRIZ theory

The Law of Five-Dimensional Equilibrium

Functional realizability | Aesthetic appeal | Production feasibility

Use Security | Environmentally friendly

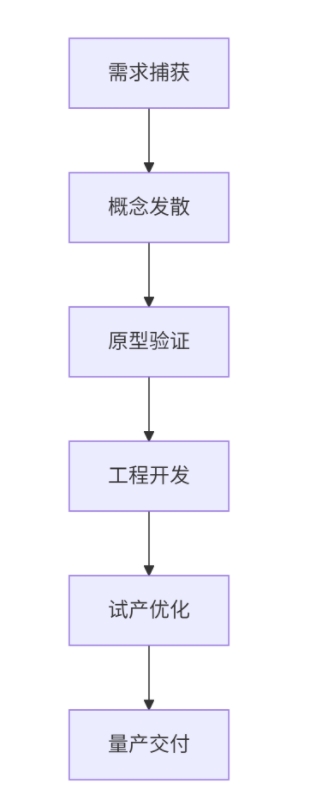

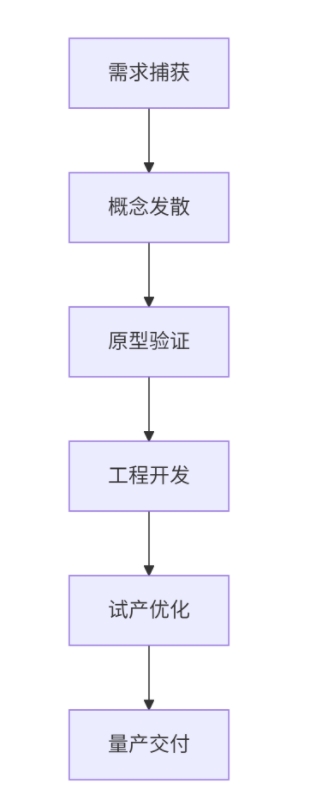

2. Product development process framework

3. Detailed explanation of the core design elements

1. Industrial Design Module

1.1 Morphological genetic design

Basic Geometry Derivation: 23 Cutting Deformation Schemes for Cubes/Cylinders/Spheres

Biomimetic pathway: 40% weight reduction rate >of honeycomb structure, 15% reduction of shark skin surface

1.2 CMF Strategy System

Elements of Decision Tree Typical Cases

Color: Pantone Trend Report, Scene Mood Board, Medical White (RAL 9016)

Material: Ashby Material Selection Matrix: Carbon Fiber Reinforced PEEK

Process DFM (Design for Manufacturing) IMD in-mold decoration technology

2. Structural Design Module

2.1 Mechanical architecture design

Topology optimization: Lightweighting (weight reduction ≥ 25%) with Altair OptiStruct

Failure Prevention:

Static Analysis (Safety Factor≥ 1.5)

Modal analysis (avoids the 50-200Hz resonance band)

2.2 Tolerance analysis system

Dimension Chain Calculations: Extreme Value/Worst Case vs. Statistical RSS

Key mating surface: shaft bore with H7/g6, flatness requirement ≤ 0.1mm/m

3. Human-computer interaction module

3.1 Five Senses Experience Design

Sensory Design Strategies Testing Criteria

Visual Fitz's Law Optimizes Operating Distances Eye Movement Trajectory Heatmap Analysis

Tactile, surface roughness, Ra0.4-1.6μm range, finger friction coefficient test

Auditory Acoustic Quality Parameters (Loudness/Sharpness) Psychoacoustic AI Evaluation Model

3.2 Interaction Logic Architecture

State Machine Design: Graphical representation of finite state machines (FSMs).

Fault Tree Analysis (FTA): covers 98% of potential anomalous scenarios

4. Encyclopedia of Materials and Processes

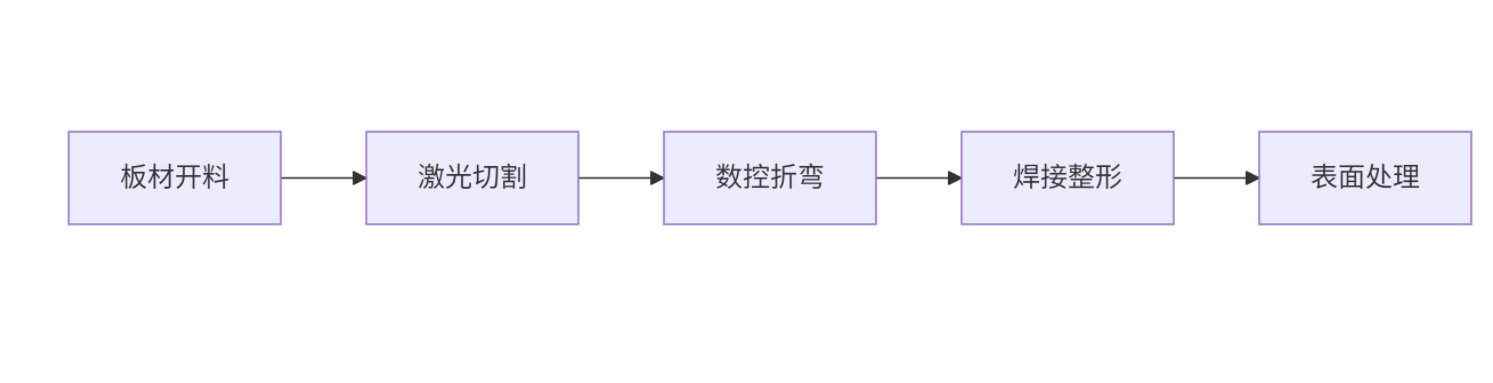

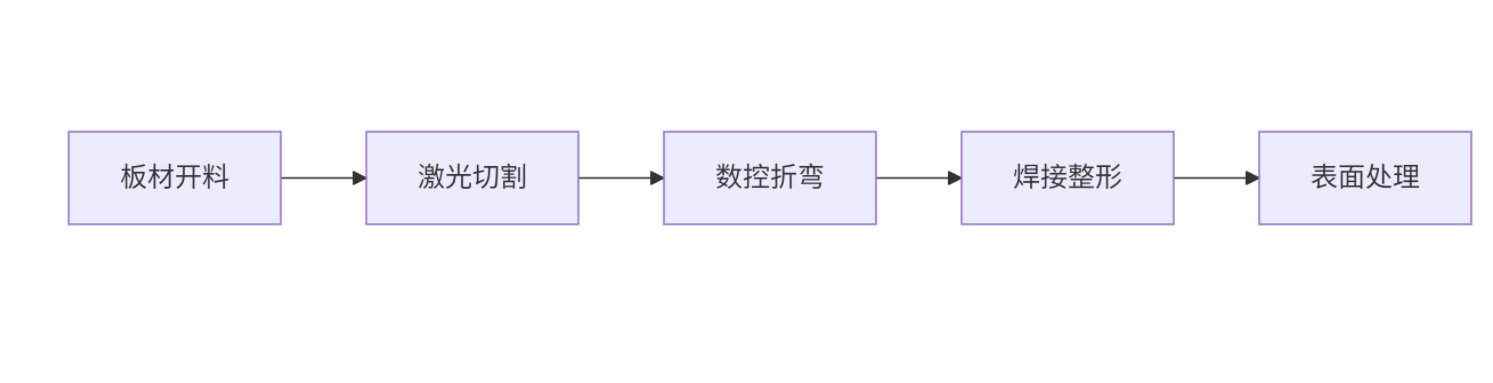

1. Metalworking process

1.1 The whole process of sheet metal

1.2 Special processes

Micro-arc oxidation: film thickness 50-100μm, hardness HV800

Metal Injection Molding (MIM): Suitable for complex and small parts (accuracy ± 0.3%)

2. Plastic molding technology

Process Wall thickness range Draft angle requirements Applicable materials

Injection molded 1-5mm ≥1° ABS/PC/PP

Blow molded 0.5-4mm symmetrical structure HDPE/PET

Blister molded 0.2-2mm freeform PVC/PS

5. Verification and testing system

1. Reliability Verification Matrix

The type of test is based on the key parameters

Environmental test IEC 60068 temperature cycle -40°C~85°C

Mechanical Test ISTA 3A Random Vibration 5Grms

Endurance Test MIL-STD-810 Key life 500,000 cycles

2. User scenario simulation

Flow analysis: Draw user flow diagram (including > 20 touchpoints)

Extreme Use Test: 95th Percentile User Strength Simulation (Grip Strength≥50N)

6. Innovation toolbox

1. Convergence of cutting-edge technologies

Smart Materials: Shape memory alloy automatically adjusts the opening of heat dissipation holes

Digital twins: ANSYS Twin Builder builds virtual prototypes

Additive Manufacturing: SLM metal 3D printing of topology-optimized structures

2. Design thinking tools

Contradiction Matrix: 40 engineering parameters to resolve conflicts

Nine-screen method: Expand the horizon of innovation in the dimension of time and space

7. Mass production connection specification

1. Design handover criteria

Drawing Specifications:

Third angle projection method

GD&T Geometric Tolerance Annotation (ASME Y14.5)

BOM List:

The material is UL recognized

ROHS Declaration of Conformity for Surface Treatment

2. Mold acceptance criteria

Injection Molds:

Cavity polished to SPI A2 grade (Ra≤0.025 μm)

Life≥ 500,000 times (H13 steel quenching HRC48-52)

Precision Design

Precision Design with us:15302653652

with us:15302653652