1. In-depth analysis of the design

1. Morphological language and visual tension

Geometric deconstructivism

Adopt a double-layer nested structure of "outer square and inner circle":

Outer layer: 30° bevel cut cube sheet metal frame (matte white paint)

Inner layer: cylindrical transparent ice tank (gradient blue glass)

Visual logic: Through the contrast between rigid metal and soft curves, it is a metaphor for "the temperature sense of ice and the precision of machinery".

Dynamic visual guidance

The top operating area is tilted 12° to guide the eye to focus on the touchscreen with a Z-shaped fold line

Parametric cut-out textures (honeycomb/fractal geometry) on the side to create a flow of light and shadow depending on the viewing angle

2. CMF Design Advanced Strategy

element

Technical solutions

User experience goals

Color: Matte White (Pantone 11-0602 TCX) Main Color: Cleanliness is enhanced

Material: Aluminum-galvanized steel sheet (40% increase in corrosion resistance) Extend the life of outdoor use scenarios

Surface treatment Micro-arc oxidation process (hardness HV≥400) Optimized scratch resistance

Key Details:

"Concealed drainage trough" design at the sheet metal bend (3° inclination angle to prevent condensate retention)

Control panel glass with AG anti-glare treatment (reflectivity ≤8%)

3. Innovative dimension of human-computer interaction

Multimodal Interaction System:

Touch: Capacitive sliding temperature adjustment (sensitivity 0.5mm sensing)

Voice: Directional microphone array (wake-up rate within 5m≥95%)

Gestures: The TOF sensor recognizes the wave to switch modes

Emotional Feedback Design:

When the ice is made, the bottom of the ice tank projects a dynamic light effect of the Northern Lights

Water shortage alarm is indicated by 20Hz low-frequency vibration with increasing amplitude (non-noise interference)

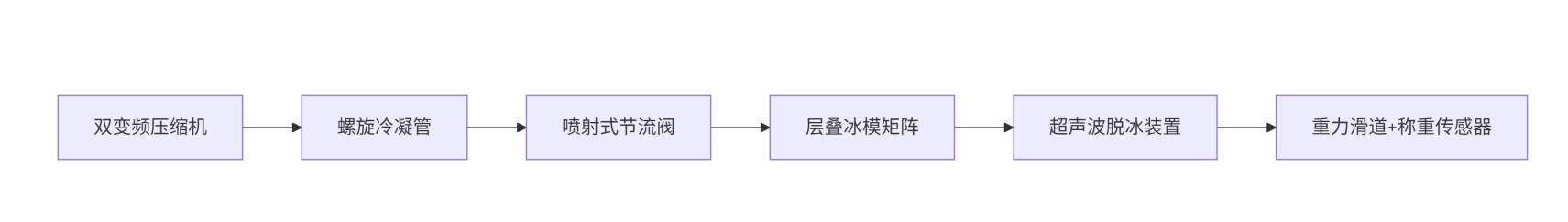

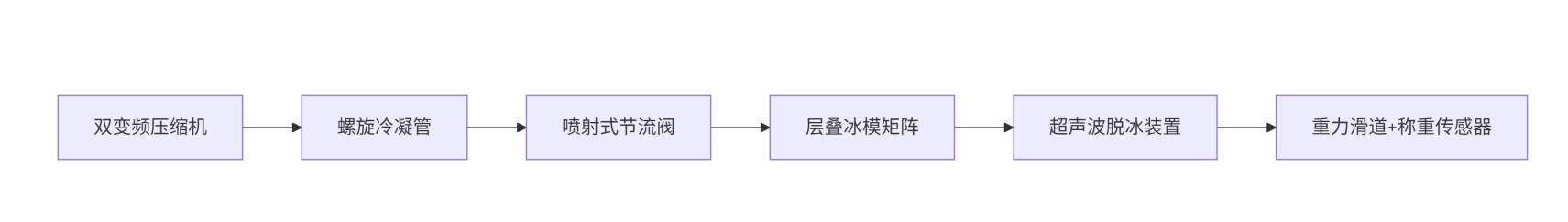

Innovative architecture for thermodynamic systems

Key Parameters:

Ice-making efficiency: 8 minutes/batch (when ice thickness is 3mm)

Energy consumption ratio: COP≥2.1 (national standard first-class energy efficiency)

Noise control: 25dB for standby ≤, 42dB for ≤ operation

2. Sheet metal structure engineering details

Process chain:

Laser cutting→ hydraulic bulging→ robotic bending→ plasma welding→ nano-spraying

Strength Verification:

Load-bearing frame: 1.5mm aluminum-galvanized steel sheet, verified by ANSYS simulation to carry 50kg of static pressure

Seismic design: Silicone shock absorbing pads installed at four corners (damping coefficient 0.25, passed ISTA 3A transportation test)

3. Breakthrough in maintainability design

Quick Release Module System:

Three-step disassembly: (1) unscrew the magnetic cover (2) unplug and unplug the power supply interface (3) pull out the evaporator assembly with the slide rail

Self-diagnosis system:

Fault codes are displayed via LED matrix (e.g. E01 = water level sensor abnormality)

Bluetooth connection to the mobile phone to generate a 3D exploding diagram to guide maintenance

3. Integration of innovative design cases and technologies

1. Transparent mechanical aesthetics

A "mechanical viewing window" is set up on the side and electrochromic glass is used:

Fogging hides the internal structure during standby

Transparent display of the dynamics of the skate maker set during operation

2. Ice crystal growth control system

Crystallization direction is controlled by piezoelectric ceramic vibration to generate diamond-shaped transparent ice (turbidity≤5NTU)

The surface of the ice mold is coated with graphene coating (thermal conductivity 5300W/m·K) to accelerate heat transfer

3. Artificial intelligence optimization system

Built-in AI learning chip:

Forecast ice production demand based on frequency of use (start 30 minutes in advance)

Automatically adjusts compressor speed by microphone recognition of ambient noise

4. Design verification and mass production preparation

1. Extreme Environment Test Matrix

Test Item Condition Acceptance Criteria

High temperature and humidity 40°C/95%RH for 72 hours Sheet metal without rust and coating without blistering

Low temperature cold shock -25°C→25°C cycle 20 times, no embrittlement of plastic parts

Salt spray corrosion 5% NaCl solution spray 96h metal surface corrosion area <3%

2. Ergonomic validation

Operating Height: 750mm (in line with the 50th percentile elbow height for Asian women)

Knob torque: 0.18N·m (Optimal operating resistance verified by Fitts' law)

3. Mass production feasibility analysis

Mould cost control:

Sheet metal parts adopt universal modules (80% of molds can be reused to series products)

IMD injection moulding process for transparent components (reduces secondary operations)

5. Cutting-edge trend integration plan

1. Closed loop of sustainable design

Material: Recycled ocean plastic for shell (30% ≥)

Energy: Photovoltaic energy storage version (optional solar panels, daily power generation ≥0.5kWh)

2. Metaverse interactive expansion

Digital twin system: View virtual operating data (e.g. refrigerant pressure, energy consumption curve) through AR glasses

NFT Digital Collection: Limited edition skins can be written into the device's LED display system via the blockchain

3. Biomimetic applications

Penguin feather structure: The gradient density arrangement of the fin's bionic penguin feathers improves the heat dissipation efficiency by 15%.

Polar bear hair hollow principle: the vacuum insulation layer design reduces the cooling loss by 30%.

6. Design a visualization strategy

Technical Illustration:

Sheet metal development diagram to mark key bending lines (with K-factor compensation value)

Thermodynamic simulation cloud diagram showing airflow path optimization

Scene Rendering:

Pairing with the cocktail-making process (highlighting the transparent texture of the ice cubes)

Industrial laboratory scenario (emphasizing technical reliability)

epilogue

Ice machine design needs to strike a balance between "mechanical aesthetics" and "functionalism" through:

Restrained expression of CMF (e.g. matte white to reduce visual noise)

Engineering innovation invisibility (e.g., embedding AI chips into sheet metal skeletons)

Implantation of emotional touchpoints (e.g. Northern Lights projection to enhance the sense of ceremony)

Precision Design

Precision Design with us:15302653652

with us:15302653652