In industrial production, due to uncontrollable production conditions and transportation environments, products often have defects such as appearance scratches, crushes, scratches and different sizes. Traditional manual inspection is slow, inaccurate, and prone to errors or missed inspections, which cannot meet the higher requirements of market competition for product quality, appearance and production capacity. In order to solve these problems, enterprises urgently need to turn to machine vision automatic inspection to achieve fully automatic and intelligent appearance inspection and sorting to meet the huge market demand.

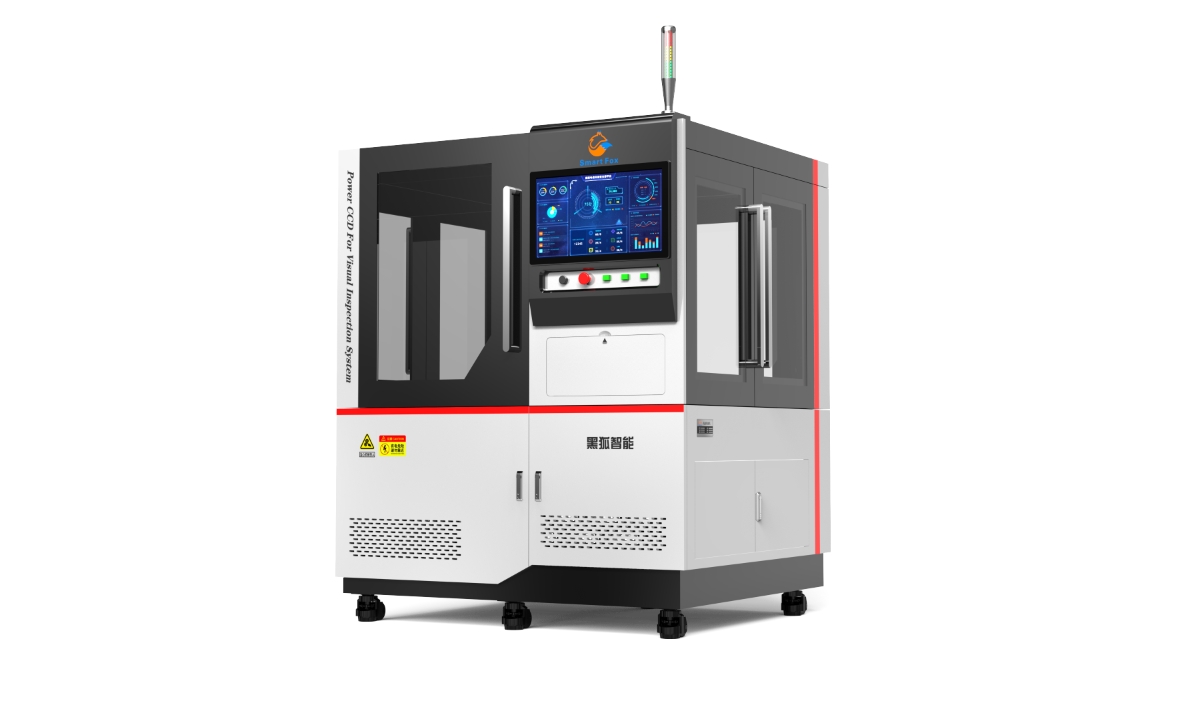

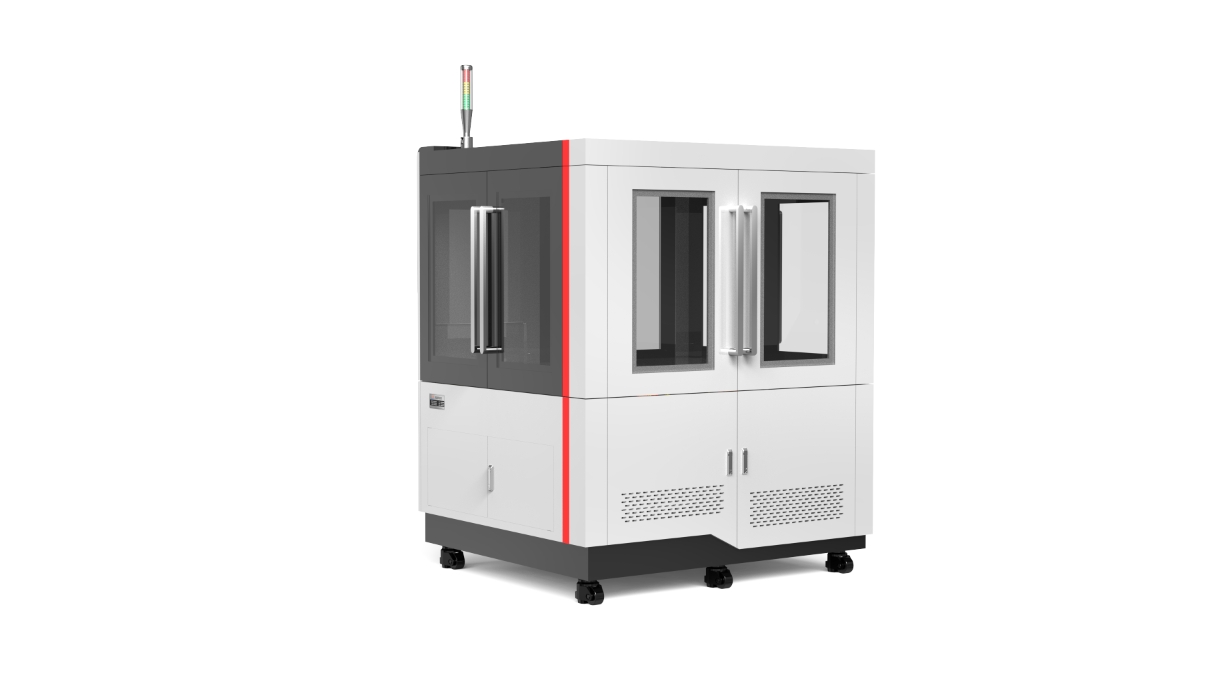

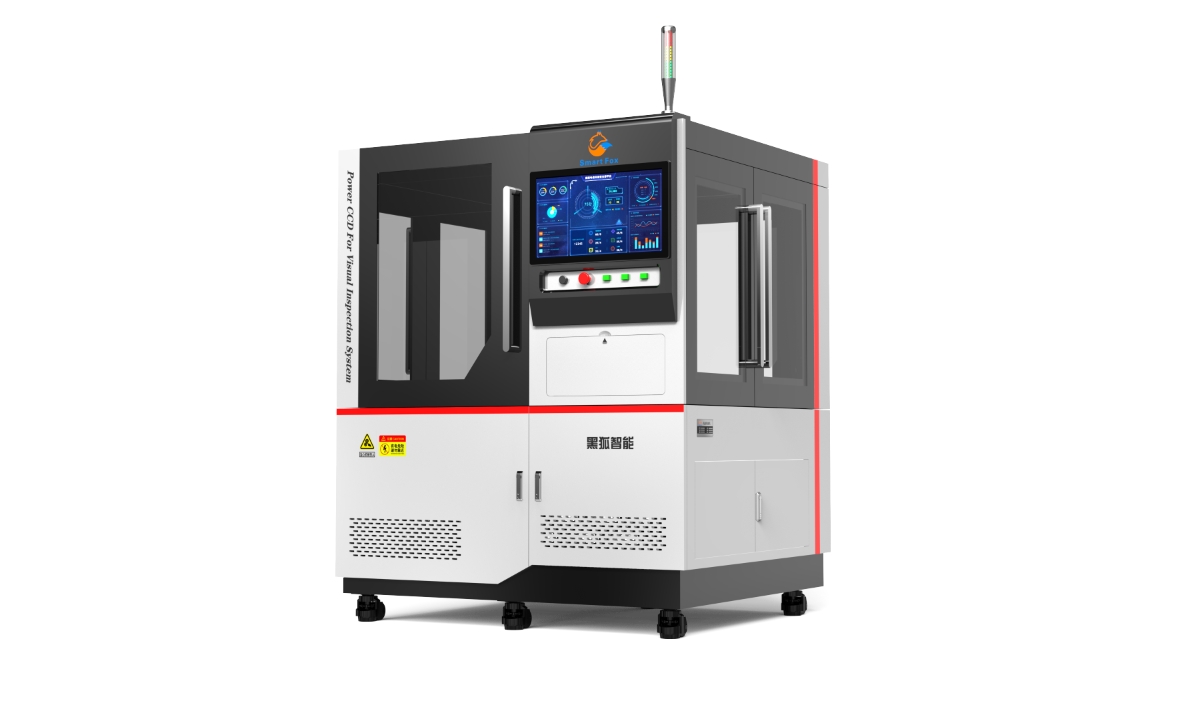

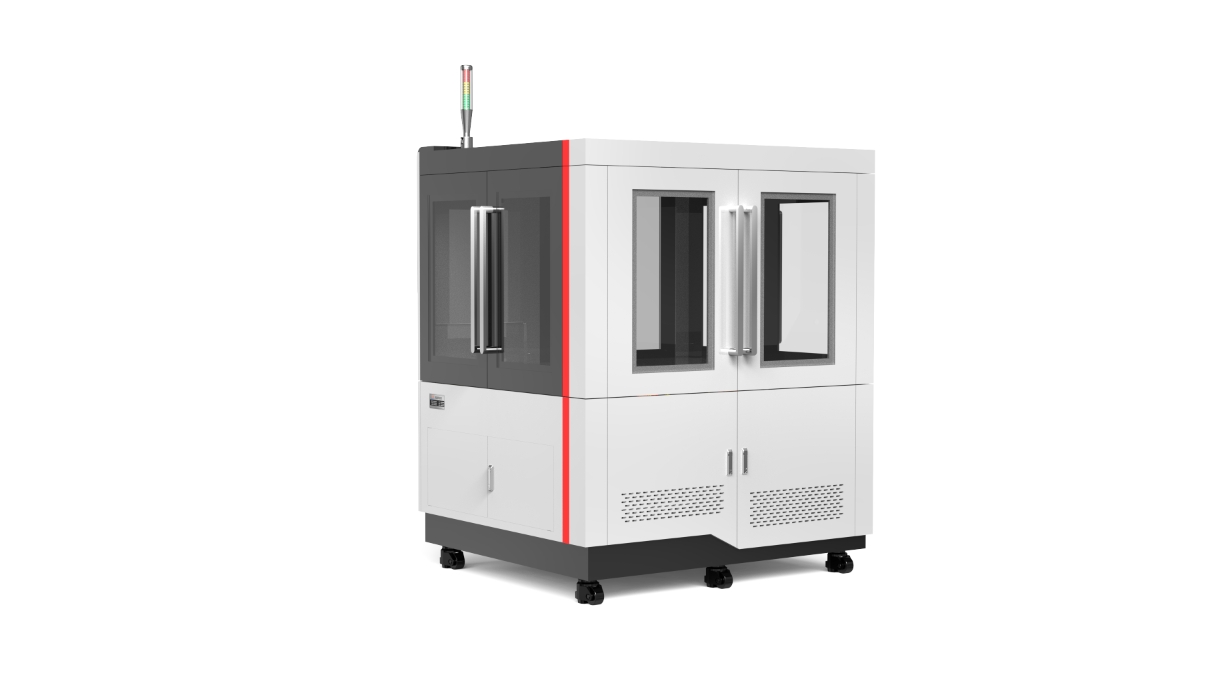

The optical screening machine is a specially designed inspection equipment for the size and appearance defects of the parts. It uses the vibrating plate feeding mechanism to automatically convey the material to the glass turntable, and the material is visually inspected through the machine vision system. The motion control card realizes the constant speed rotation of the turntable and the control of the material position, and uses the encoder feedback and hardware position comparison output to control the CCD camera and air blowing port device in different positions. In this way, fully automatic multi-faceted appearance and size inspection and screening are realized, which greatly improves production efficiency and saves labor costs.

Precision Design

Precision Design with us:15302653652

with us:15302653652